| Categories | U Trough Screw Conveyor |

|---|---|

| Brand Name: | Jinrui |

| Model Number: | LS300 |

| Certification: | ISO |

| Place of Origin: | Henan |

| MOQ: | 1 piece |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 piece per Month |

| Delivery Time: | 10 work days |

| Packaging Details: | accroding to the machine size packed into different size woodcase |

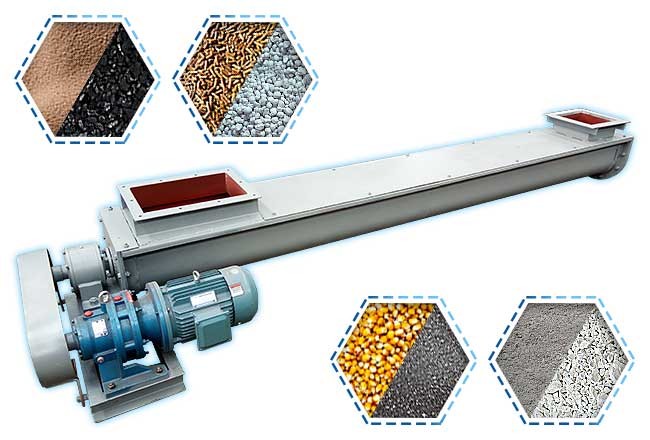

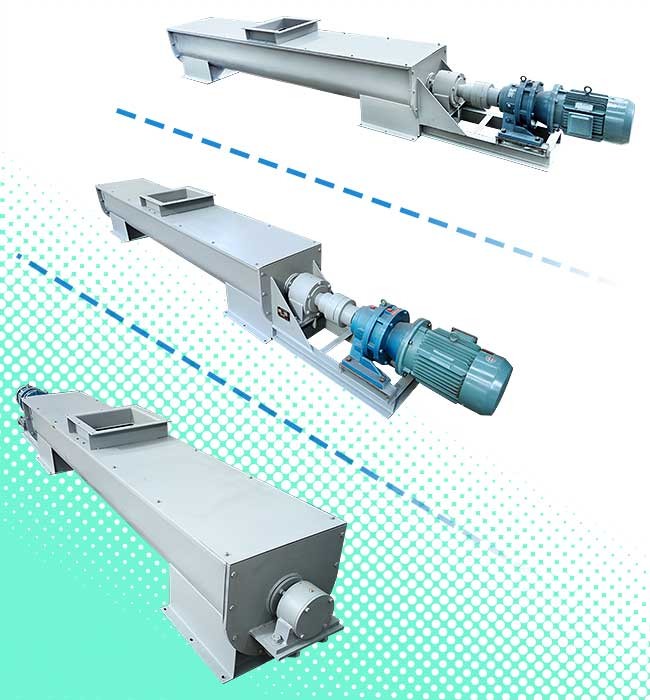

| Product name: | U Trough Stainless Steel Screw Conveyor With Cover |

| Thickness of screw: | 6 mm |

| Diameter: | 200mm/300/400/800mm/aacoridng to capacity |

| Application: | wood chips, sawdust,sand,ore |

| Installation: | horizontal / inclined |

| Material: | SS304,SS316L |

The LS screw conveyor is designed and manufactured in accordance with the JB/T 7679-95 "Screw Conveyor" standard. It is a replacement product of the GX screw conveyor. Screw conveyor, commonly known as auger, is a widely used conveying equipment in the mining, feed, grain and oil, and construction industries. It is made of steel and used to convey powder or solid particles and other chemical and building materials products.

II. Working principle and Applictaion

The screw conveyor uses the rotating screw to move the conveyed material along the fixed casing to carry out the conveying work. The head and tail bearings are moved to the outside of the casing. The hanging bearing adopts a sliding bearing and is equipped with a dust-proof sealing device. The bearing bush is generally used Powder metallurgy, the conveying cement adopts felt bearing bushes, and the suspension shaft and the screw shaft are connected by sliding blocks

Screw conveyors are suitable for various industries, such as building materials, chemical industry, electric power, metallurgy, coal, food and other industries, and are suitable for horizontal or inclined conveying powder, granular and small lump materials, such as coal, ash, slag, cement, grain, etc. , The material temperature is less than 200℃. The screw machine is not suitable for conveying materials that are perishable, viscous, and easily agglomerated.

1. Large carrying capacity, safety and reliability.

2. Strong adaptability, convenient installation and maintenance, and long life.

3. The whole machine is small in size and high in speed, ensuring fast and uniform delivery.

4. The discharge end is equipped with a cleaning device, the whole machine has low noise, strong adaptability, and flexible layout of the inlet and outlet positions.

5. Good airtightness, the shell is made of seamless steel pipes, and the ends are connected by flanges to form a whole, with good rigidity.

| Model | Diameter mm | Pitch mm | Speed r/min | Standard Capacity(m3/h) | Speed r/min | Standard Capacity(m3/h) | Speed r/min | Standard Capacity(m3/h) | ||||||

| φ0.45 | φ0.33 | φ0.15 | φ0.45 | φ0.33 | φ0.15 | φ0.45 | φ0.33 | φ0.15 | ||||||

| LS20 | 200 | 200 | 100 | 16.9 | 12.4 | 5.6 | 80 | 13.5 | 9.9 | 4.5 | 63 | 10.7 | 7.8 | 3.6 |

| LS315 | 315 | 315 | 80 | 52.9 | 38.8 | 17.6 | 63 | 41.6 | 30.5 | 13.9 | 50 | 33.1 | 24.2 | 11 |

| LS400 | 400 | 355 | 71 | 85.3 | 62.5 | 28.4 | 56 | 67.3 | 49.3 | 22.4 | 45 | 54.1 | 39.6 | 18 |

| LS500 | 500 | 400 | 63 | 133.2 | 97.7 | 44.4 | 50 | 105.8 | 77.6 | 35.3 | 40 | 84.6 | 62.0 | 28.2 |

| Material to be processed: _____ | Working environment is indoor or outdoor:________ |

| Handling capacity: ________per hour | Working environment temperature: _______ ℃ |

| Bulk Density: _____t/m3 | Installation form is horizontal or inclined : ________ |

| Conveying distance: ________ | If it is inclined,what is the inclined degree_____° |

| Material size:____mm | Water content:____% |

| Material temperature: _______ ℃ | Working power supply: _____V ______HZ ______PH |

VI.Equipment installation requirements

a. The on-site installation of the inlet and outlet should make the

flange support surface of the inlet and outlet parallel to the axis

of the screw machine; the flanges connected to it should be tightly

fitted and there should be no gaps.

b. After the screw machine is installed, check whether there is

enough lubricating oil in each oil storage place, if not enough,

add enough, and then carry out a no-load test run; check the screw

machine after running for more than 4 consecutive hours. Accuracy

of assembly: Stop immediately when an abnormality is found, and

operate after treatment until it is in a good operating state.

c. The operation of the screw machine should be stable and

reliable, and the fasteners should not be loosened. The reducer has

no oil leakage, no abnormal sound, electrical equipment is safe and

reliable, and the no-load operating power is less than 30% of the

rated power.

|