| Categories | Forged Round Bar |

|---|---|

| Brand Name: | Guangda |

| Certification: | DNV, BV, Rina, ISO, GL, ABS, LR ,CCS ,PED |

| Place of Origin: | Jiangsu China |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 500000 ton/year |

| Delivery Time: | 15-45 work days |

| Material: | C22 1.0402 |

| Heat treatment: | Annealing,Normalizing,Tempering ,QT etc . |

| Standard: | EN10250,EN10083,SEW550 etc |

| Shape: | Round, flat, hexagonal, block, etc |

| Surface: | Black, turned , rough turnned ,premachined,polish |

| Length: | Max 10000mm (10m) |

| Diameter: | φ150-1500mm |

| Trade Mark: | GD |

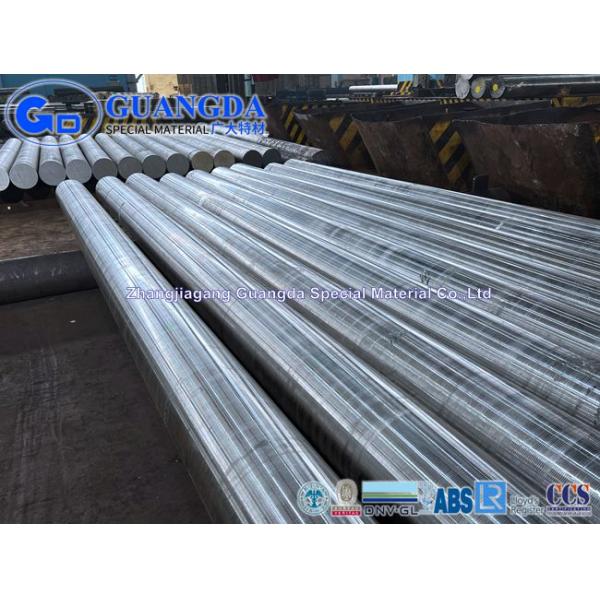

C22 1.0402 forged round bar carbon steel round bar C22 steel bar C22 steel Manufacturer

C22 is a kind of carbon structural steel, suitable for bolts, nuts, screws, tie rods, small shafts, brake gear.C22 is a kind of high quality carbon structural steel, high manganese low carbon penetration steel, good welding performance, but high hardenability, strength and plasticity.

Forged Round Bar 1.0402 C22 Product features

| Material | C22 1.0402 |

| Type | Forged bar ,round ,square, flat, block, shaft etc. |

| Diameter | φ150-1500mm |

| Length | Max 10000mm (10m) |

| Surface | Black, peeled, polishing, bright, sand blast, hair line, etc. |

| Application | suitable for bolts, nuts, screws, tie rods, small shafts, brake gear. |

| Tensile strength test | DIN EN ISO 6892-1 |

| Impact test | DIN EN ISO 148-1 |

| UT | DIN EN10228 Quality-Class 3 C/c or D/d |

| Grain size | ASTM E112 / EN ISO 643 |

| Applicable standard | EN10250,EN10083,SEW550 etc |

| Certificate | EN 10204 / 3.1 3.2 |

Forged Round Bar 1.0402 C22 Chemical Compostion

| Standard | Steel designation name | Number | C | Si Max | Mn | P Max | S Max | Cr Max | Mo Max | Ni Max | Cr+Mo+Ni Max | Al Min |

| EN10250 | C22 | 1.0402 | 0.17-0.24 | 0.40 | 0.40-0.70 | 0.045 | 0.045 | 0.40 | 0.10 | 0.40 | 0.63 | - |

Forged Round Bar 1.0402 C22 Permissible deviations

| Permissible deviations between the producct analysis and the

limiting values given in Table 1 for the cast analysis EN10250 | ||

| Element | Permissible maximum content in the cast analysis % | Permissible deviation % |

| Carbon | <0.55 | ±0.02 |

| >0.55 ≤0.65 | ±0.03 | |

| Silicon | ≤0.40 | ±0.03 |

| >0.40 | ±0.04 | |

| Manganese | ≤1.00 | ±0.04 |

| >1.00 ≤1.65 | ±0.06 | |

| Phosphorus | ≤0.045 | +0.005 |

| Sulfur | ≤0.045 | +0.005 |

| Chromium | ≤0.40 | +0.05 |

| Molybdenum | ≤0.10 | +0.03 |

| Nickel | ≤0.40 | +0.05 |

| Aluminium | ≥0.020 | -0.005 |

Forged Round Bar 1.0402 C22 Mechanical properties

| Mechanical properties in the normalized and normalized and tempered

conditions Thickness of ruling section tR | ||||||||||||||||||||||||||

| Steel designation | tR≤100mm | 100<tR≤250mm | 250<tR≤500mm | 500<tR≤1000mm3) | ||||||||||||||||||||||

| Standard | Name | Number | Remin N/mm² | Rmmin N/mm² | A min % | KV min J | Remin N/mm² | Rmmin N/mm² | A min% | KV min J | Remin N/mm² | Rmmin N/mm² | A min % | KV min J | Remin N/mm² | Rmmin N/mm² | A min% | KV min J | ||||||||

| l 1) | tr 1) | l 1) | tr 1) | l 1) | tr 1) | l 1) | tr 1) | l 1) | tr 1) | l 1) | tr 1) | l 1) | tr 1) | l 1) | tr 1) | |||||||||||

| EN10250 | C22 | 1.0402 | 210 | 410 | 25 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Forged Round Bar 1.0402 C22 Heat treatment

| Heat treatment EN10250 | |||||

| Steel designation | Quenching temperature ℃ | Cooling medium | Tempering temperature ℃ | Normalizing temperature ℃ | |

| Name | Number | ||||

| C22 | 1.0402 | 860 to 900 | Water | 550 to 660 | 860 to 920 |

About Guangda For forged round bar

carbon steel bar

carbon steel round bar

carbon steel flat bar

|