| Categories | Tungsten Carbide Rod |

|---|---|

| Brand Name: | Zhuzhou Jintai Cemented Carbide |

| Model Number: | Various |

| Certification: | SGS ISO |

| Place of Origin: | Hunan, China |

| MOQ: | Negotiable, sample order acceptable |

| Price: | Negotiable, depends on carbide grade and quantity. |

| Supply Ability: | 300 Ton/Tons per Month |

| Delivery Time: | 7-25 days, depends on quantity. |

| Packaging Details: | Pack with shock resistance foam first in plastic box, and then carton boxes outside. Or pack according to your request |

| Payment Terms: | L/C, T/T, Western Union |

| Alloy: | K01, K10, K20 carbide grade |

| Particle: | 0.2-1.7um |

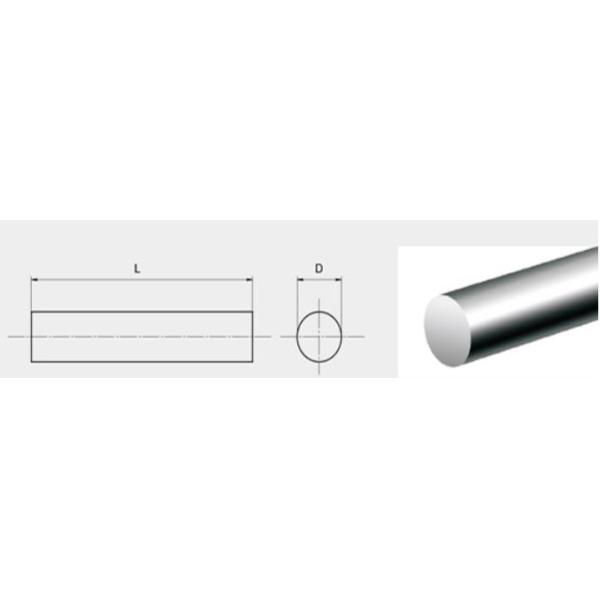

| Product name: | Factory Sale Yg10x 330mm Tungsten Carbide Rods Cemented Carbide Rods |

| Material: | virgin carbide |

| Surface: | h6 |

| Certificate: | ISO |

| Color: | Silver Gray |

| Application: | drilling and milling Machinery Tool part |

Factory Sale Yg10x 330mm Tungsten Carbide Rods Cemented Carbide Rods

Application

Widely used in the production and processing fields:such as micro-drills in PCB industry, electrodes rods in photoelectric communication industry,tungsten steel drills,drill shanks and wear-resistant precision parts in mechanical processing industry,are selected materials for integral NC milling cutters and hole-cutting cutters such as engraving cutters

Material composition:

1.Physical Properties:

A) Hardness greater than or equal to 92.8 HRA;

B) Density greater than or equal to 14.2 g/cm³;

C) TRS greater than or equal to 4200 N/mm²;

D) Free of ETA phase condition;

E) No contamination by other materials;

F) Porosity = A00 / B00 / C00 ;

G) Uniform and consistent grain size. No grain size can be larger

than specified.

H) Chromium carbide grain growth inhibitor only.

2.All the production, coatings are used in Germany, Switzerland,

processing equipment;

3.It's proposed cutting less than 60HRC;

Properties of cemented carbide grades recommended rods | |||||||

Grade | Chemical composition | Physical data | Grain size of WC(um) | ||||

WC | Co | Others | Density(g/cm³) | Hardness(HV3) | TRS(MPa) | ||

YL10.1 | 93.5% | 6.0% | 0.5% | 14.88-15.04 | 1580±50 | 2500 | 1.2-1.7 |

YL10.2 | 89.5% | 10.0% | 0.5% | 14.4-14.55 | 1600±50 | 4000 | 0.8 |

YL10.5 | 89.7% | 9.5% | 0.8% | 14.4-14.55 | 1550±50 | 3800 | 0.7-0.9 |

YL50 | 85.0% | 15.0% | 13.86-14.10 | 1095 | 2060 | 0.4-0.6 | |

YU06 | 93.0% | 6.0% | 1.0% | 14.7-14.8 | 2050 | 3000 | 0.2-0.4 |

YU08 | 91.0% | 8.0% | 1.0% | 14.56-14.65 | 1900 | 4000 | 0.2-0.4 |

YU09 | 89.8% | 9.0% | 1.2% | 14.36-14.50 | 1950 | 3900 | 0.2-0.4 |

YU12 | 87.0% | 12.0% | 1.0% | 14.05-14.15 | 1750 | 4000 | 0.2-0.4 |

YF06 | 93.5% | 6.0% | 0.5% | 14.86-14.96 | 1800 | 3800 | 0.4-0.6 |

YF08 | 91.4% | 8.0% | 0.6% | 14.55-14.65 | 1800 | 3900 | 0.4-0.6 |

YG6X | 93.5% | 6.0% | 0.5% | 14.8-15.10 | 91 | 1560 | 1.0 |

YG8 | 92.0% | 8.0% | 14.6-14.9 | 89.5 | 1840 | 1.2-1.6 | |

~ Customized Tungsten carbide products are available!

| Type | D(mm) | Tol. Of diameter(mm) | L(mm) | Tol. Of diameter(mm) |

| ¢1.0*330 | 1.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢2.0*330 | 2.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢3.0*330 | 3.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢4.0*330 | 4.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢5.0*330 | 5.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢6.0*330 | 6.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢7.0*330 | 7.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢8.0*330 | 8.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢9.0*330 | 9.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢10.0*330 | 10.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢11.0*330 | 11.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢12.0*330 | 12.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢13.0*330 | 13.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢14.0*330 | 14.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢15.0*330 | 15.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢16.0*330 | 16.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢17.0*330 | 17.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢18.0*330 | 18.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢19.0*330 | 19.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢20.0*330 | 20.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢21.0*330 | 21.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢22.0*330 | 22.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢23.0*330 | 23.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢24.0*330 | 24.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢25.0*330 | 25.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢26.0*330 | 26.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢27.0*330 | 27.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢28.0*330 | 28.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢29.0*330 | 29.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢30.0*330 | 30.0 | +0.2~+0.8 | 330 | 0~+5.0 |

|